Dingsheng Group to share with you the latest industry news

To ensure our customer’s satisfaction in their manufacturing processes using our product, we offer a range of support services, including various product verification tasks and analysis of issues and defects that arise in daily production.

We are fully committed to providing comprehensive support, ensuring that our customers can use our products with confidence and achieve successful manufacturing outcomes.

Our experienced engineers, specializing in joining technology, provide a technical approach with a comprehensive range of analytical, verification, and inspection equipment. We conduct analysis from physical, chemical, and electrical perspectives to identify root causes and deliver tailored solutions.

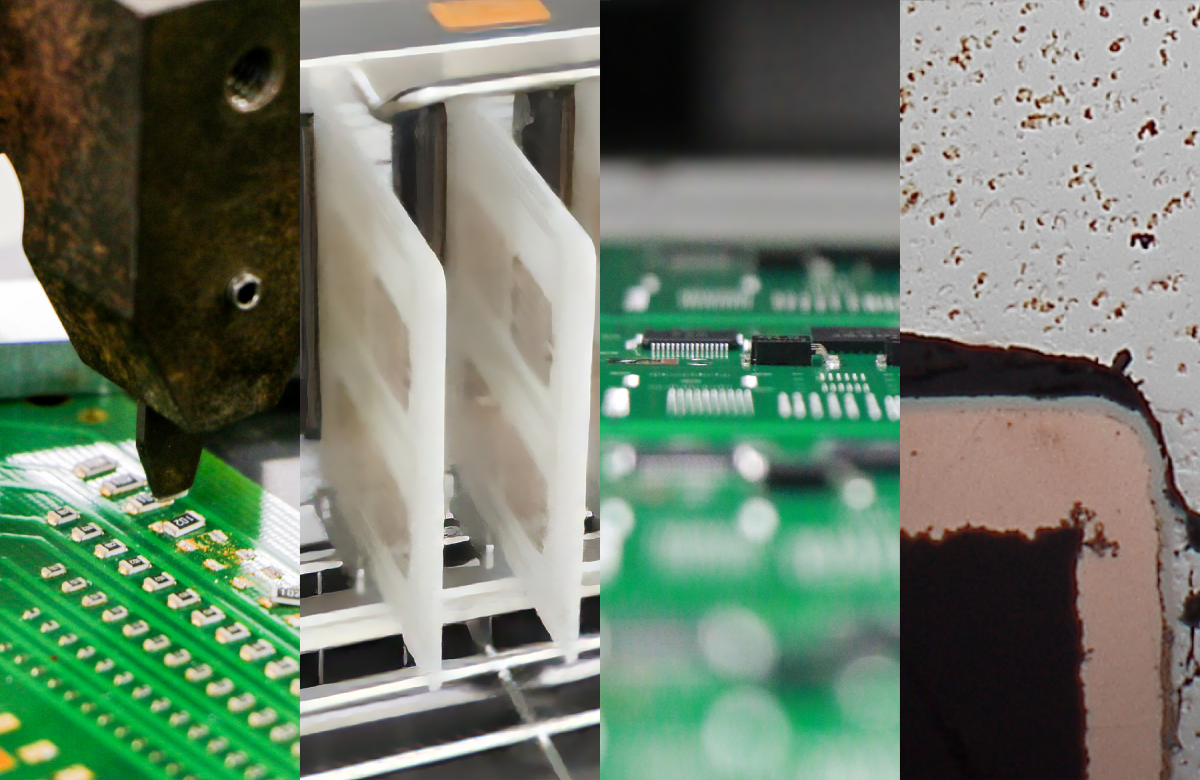

We support the optimization of process conditions to ensure that Koki products achieve peak performance and quality. We replicate the customer's assembly Environment - such as printing conditions and reflow Profiles - on our test lines to tailor the process accordingly.

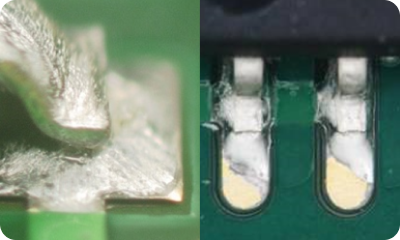

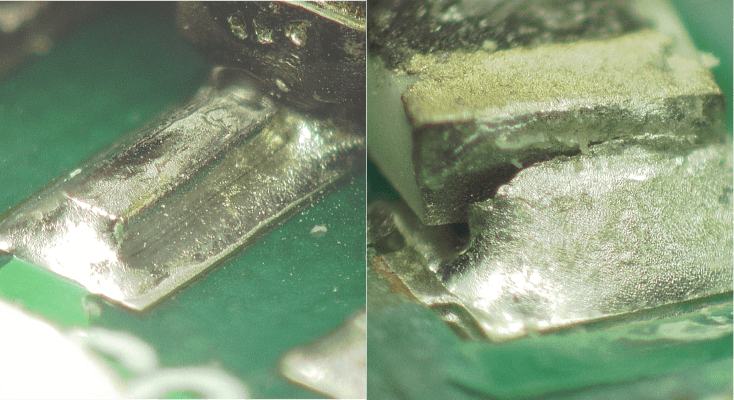

Observes Defective Point

Identifies Nature of Defect

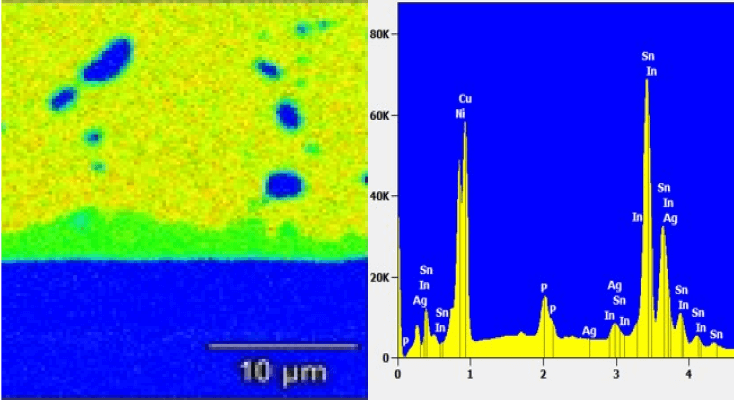

Evaluates Quality of Plating

Identifies Contaminating Element

Analyzes Contaminating Element

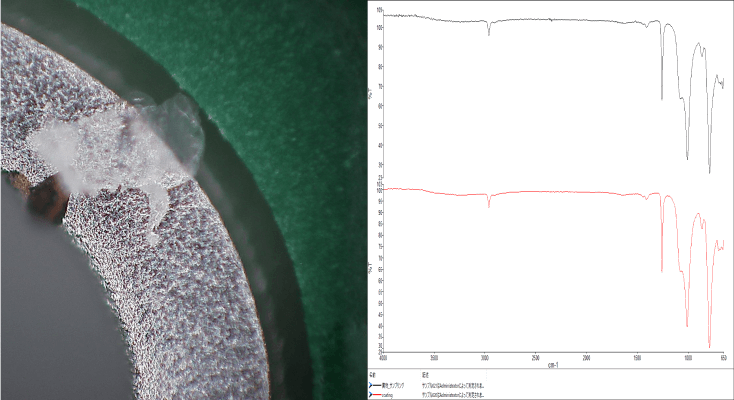

Identifies Contaminating Substance

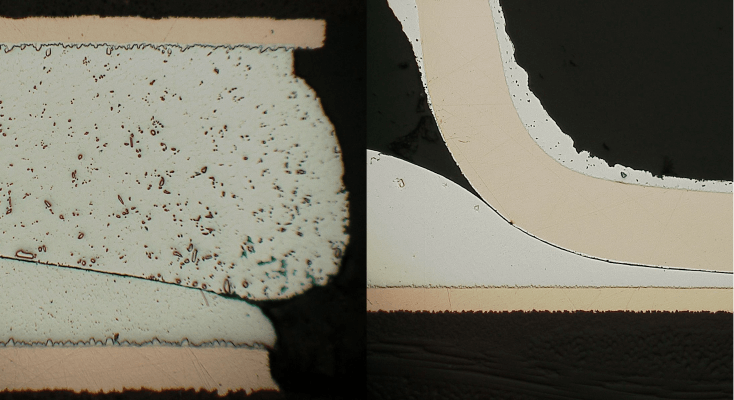

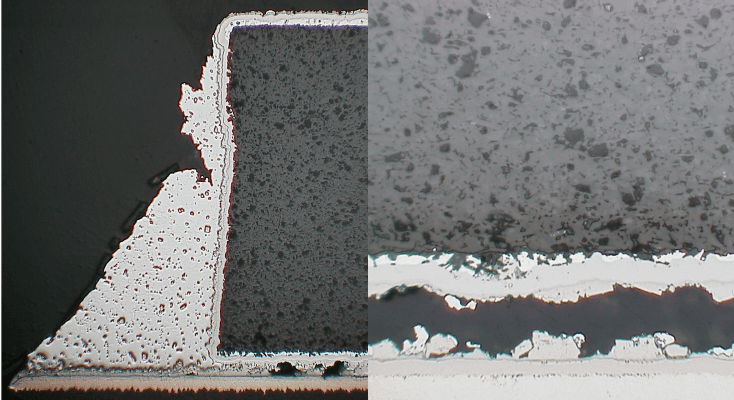

Evaluates IMC (Intermetallic Compound)

Evaluates Crystalline Structure

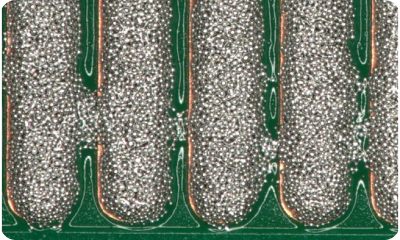

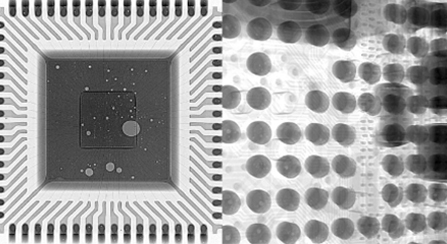

Observes Defect (eg. Head-in-Pillow, Tombstone)

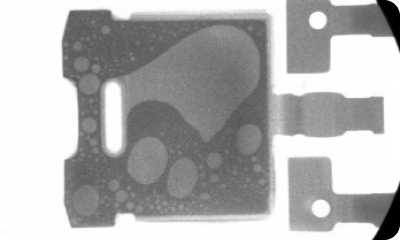

Observes Voiding

Observes Head-in-Pillow Defects

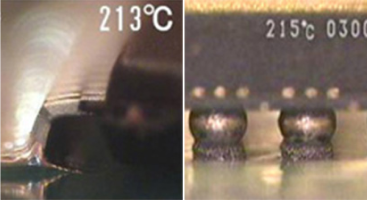

Simulates Wetting Behavior

Observes Warpage of Component and Board

Suggests Recommended Reflow Conditions

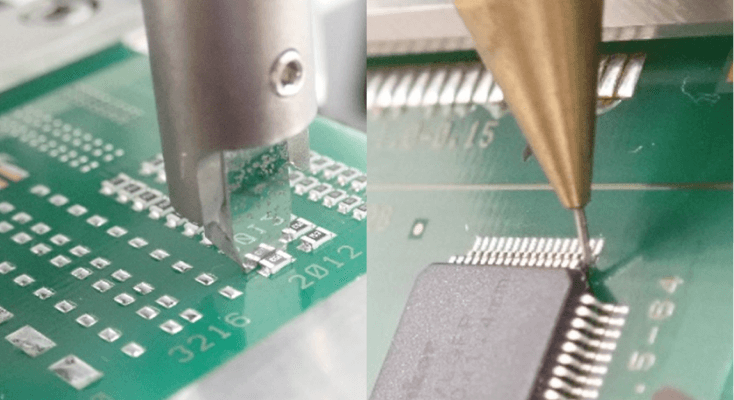

Evaluates Shear Strength

Evaluates Pull Strength

Observes Breakage Mode

Evaluates Joint Durability

Observes Growth of IMC

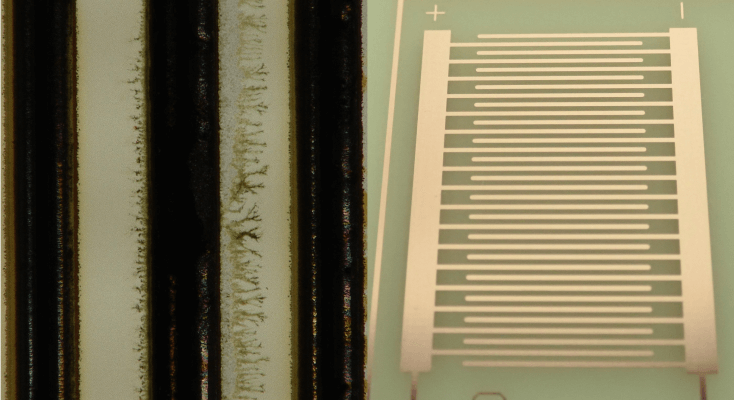

Observes Electro-Migration in Thermohygrostat

Evaluates Voltage Applied SIR

Evaluates Drying at Normal Temp